Metal detecting holidays in England with the World's most successful metal detecting club.20 years plus.

Twinned with Midwest Historical Research Society USA.

Bells - Crotal, Rumbler, Cow, Hawking, sheep bells and Whistles |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Crotal and rumber

bells were

used with small animals up to the largest beast.They were also used

for by humans as good luck charms, dancing and religious purposes. The

bells are mentioned in the Bible !! |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Rumbler bells maufacturer marks table

Tiny Medieval jester/rumbler bell The circular bell is made up of four petal-like tabs folded at the base with a small ‘pea’ inside that is no longer loose. On top is an integral circular attachment loop and decorating the body of the bell, from the attachment loop to the base, are four vertical strips of raised chevron decoration. Bells of this type were produced only until about the end of the 13th century. (Cf. MoL, Dress Accessories, 1668-1671; Mitchiner, Medieval & Secular Badges, 356.)

The earliest crotal bells found in England date to the beginning of the 13th century. They are of tin and were cast as open bells with an integral suspension loop and four ‘petals’ forming the lower body. The pellet, also of cast tin, was placed inside the open-ended bell, and the four petals were pushed inwards to meet at the centre and enclose it.

Sheet-metal crotal bell

Two-piece cast crotal bell

Alongside the early cast crotals, copper and copper-alloy bells of sheet metal were produced. The body of these is made in two halves, formed by hammering the sheet into shaped moulds, and joined together, after inserting the iron ‘pea’, with a lead/tin solder. On the very earliest of this type, the loop was made of circular-section wire, which was inserted through a small hole in the top of the bell and its ends splayed in the manner of a modern split-pin. Slightly later, a narrow strip of sheeting was used instead of wire, and was either fitted in the same way, or formed into a ring and soldered to the top of the bell as on the example illustrated. Bells of this type have been recovered from secure contexts that span the date range circa mid-13th to mid-15th century. They are also found in a wide range of sizes, at least from 13mm to 34mm diameter, suggesting a variety of different uses. (Cf. MoL, Dress Accessories, 1644-1667; B Read, History Beneath Our Feet. p.55, No.2; Mitchiner, Medieval & Secular Badges, 350.) A development that occurs during the late 14th century is the casting of bells in two halves, which were then soldered at the horizontal joint line after inserting the pellet.

The one-piece cast crotal bell represents a triumph of ingenuity, the manufacturing principle of which has not changed in 400 years. Details of the process, as now implemented, are fully described below, but essentially the pellet is contained within the sand core during the moulding process, thus eliminating the need either to solder a joint, or to bend the body into shape. Bells made in this way are readily identifiable by the two ‘sound holes’ in the upper half of the body. These are, in fact, primarily to facilitate positioning of the core, rather than for transmission of the sound. The two-part moulds for bells of this type are split at the girth rib on the bell, and consequently there are no vertical mould-joint lines evident on them. The girth rib serves the useful purpose of accommodating any minor misalignment between the two halves of the mould, as well as strengthening the bell and retaining the traditional appearance of those with a soldered joint. From the 16th century, the one-piece cast crotal rendered most other types of construction obsolete. One exception was the sheet-metal type, which, has been produced ever since for hawking bells, pet bells and other uses where a small size and lightness are key considerations. (Since the 18th century, sheet-metal bells have been produced by a die-forming process, rather than the metal being hammered into a mould.) As the method of manufacturing the one-piece bell has changed little since the Tudor period, the determination of their chronology is dependent on differences of detail, rather than basic manufacturing concept. Close dating is often difficult, unless the bells can be associated with a maker whose period of operation is known from documentary sources. This is rarely the case prior to the late 17th century, when some makers began to put their initials on the bells. The following details are helpful in determining an approximate date.

Drilled suspension loops on one-piece cast crotal bells of circa 16th to mid-17th century date

During the 17th century, an innovation in the production process eliminated the need to carry out a drilling operation. Instead, by making the pattern with a detachable ‘sprue-piece’, it was possible to create a suspension lug with a cored hole. The sand in the upper moulding box was packed around the pattern (see drawing), which was then withdrawn, as normal, from the underside.

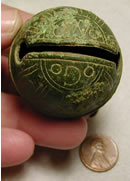

Post-medieval crotal bells may be either plain or decorated, and decoration may be applied to both the upper and lower hemispheres, or to the lower hemisphere only. Where both hemispheres are decorated, the respective designs may be of similar or differing types. A number of different decorative devices are used, but varieties of the so-called sunburst design (sunflower would seem more appropriate) are by far the most common. This takes the form of a number of elongated ovoid petals radiating from the centre of the hemisphere. The design is found on bells throughout the post-medieval period.

The second most likely form of on both hemispheres decoration to be found is the fish-scale pattern. This was used during the early part of the post-medieval period, but is rarely, if ever, found on bells made after the 17th century. It is often used to decorate the lower hemisphere of the bell, in combination with a sunburst design on the upper hemisphere. There are various other forms of decoration, including crowns (Civil War period?), leaves, and human and animal faces, but the vast majority of bells are either plain or have sunburst or fish-scale decoration, or a combination of these types

Bells that are decorated only on the lower hemisphere tend to be of later date, usually late 18th to mid 19th century. Those with no decoration also usually date to this later period. There are, however, exceptions to this general rule, and plain bells of early post-medieval date are also known. All the indicators discussed should be taken into consideration when dating a bell. It should also be noted that the decoration can often have a very worn appearance, and is sometimes barely discernible. It seems unlikely that such wear occurred in use, and it is probably mostly due to the use of worn-out patterns.

c 16thC Beautiful crotal bell - not seen one with face/animal design - different head on each side

Stunning 16thC crotal bell

Stunning 16thC crotal bell

Size comparison

Monster sized 18thC cow bells and size comparison to normal sized crotal bells Robert Well I Aldbourne 1760-1780 he Wells Foundry was established in 1755 by Robert I (b.1725), the only son of William Wells, a local blacksmith. Robert I ran the foundry until his death in 1781, at which time, he was working jointly with his son, Robert II (b.1756). Robert II was joined by his younger brother, James (b.1771), around 1790, and when he retired in 1798, he left James in charge. For some time, the business did very well under James, but circumstances changed, and in 1825 it went bankrupt and was sold to Thomas Mears II of the Whitechapel Foundry. Wells crotal bells are virtually identical to those produced by the Seller Foundry at York. It seems likely, therefore, as Butler suggests, that when Edward Seller II ceased trading and sold his equipment in 1761 and 1763, Robert Wells I acquired his patterns. The only initialled crotal bells currently attributed to this foundry are those marked ‘RW’, and these were probably produced even during the period when James was in sole charge.

Aldbourne Although details of only one member of this family are listed, the initials ‘WG’ occur on crotal bells that seem to span a considerable period of time and differ widely in quality. It is possible that earlier members of the family were involved in bell founding, or that the initials on the earlier and cruder bells are those of an unrelated maker. The William Gwynn listed was born in 1749 and died in 1813.

17thC Andrew Gurney of Hull crotal bells AG Little information has been traced, but Butler suggests that crotal bells with the initials ‘AG’ might be attributable to Andrew Gurney of Hull. He states, “The only church bell founder with these initials in the north of England was Andrew Gurney of Hull, whose bells bear dates of 1676 and 1678.” Hawking Whistle

Decorated hawking whistle - rare medieval example featured on the whistle museum web site Interesting link to one of our finds featured in a whistle museum, rare find

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bell clappers

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silver hawking bells

Superb decorated medieval silver hawking bell - reported as treasure to the museum |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Medieval

hawking bell fragment |

Medieval silver hawking bell fragment with maker MB |

Medieval

silver hawking bell fragment |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Medieval silver hawking bell | Medieval silver hawking bell fragment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Post medieval silver hawking bell fragment | Medieval silver hawking bell fragment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Medieval silver hawking bell fragment | Medieval silver hawking bell fragment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Acme Thunder SE &CR whistle (South Eastern and Chatham railway) 'Acme Whistles made and supplied the original stock of Thunderers for officers and senior ratings of the ill-fated Titanic ocean liner. Surviving examples discovered over the years have commanded high prices at auction and generated considerable publicity'.

Huge steam whistle ?

Victorian whistle

Various whistles

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cow Bells

Monster sized cow bells next to a normal crotal for size |

Georgian horse harness bells

|

Georgian horse harness bells |