Metal detecting holidays in England with the World's most successful metal detecting club.20 years plus.

Twinned with Midwest Historical Research Society USA.

|

Nails |

In

Britian there is early evidence of large scale nail making from Roman

times 2000 years ago. Any sizeable Roman fortress would have its 'fabrica'

or workshop where the blacksmiths would fashion the metal items needed

by the army. They left behind 7 tons of nails at the fortress of Inchtuthil

in Perthshire. In

Britian there is early evidence of large scale nail making from Roman

times 2000 years ago. Any sizeable Roman fortress would have its 'fabrica'

or workshop where the blacksmiths would fashion the metal items needed

by the army. They left behind 7 tons of nails at the fortress of Inchtuthil

in Perthshire.

For nail making, iron ore was heated with carbon to form a dense spongy mass of metal which was then fashioned into the shape of square rods and left to cool. The metal produced was wrought iron. After re-heating the rod in a forge, the blacksmith would cut off a nail length and hammer all four sides of the softened end to form a point. Then the nail maker would insert the hot nail into a hole in a nail header or anvil and with four glancing blows of the hammer would form the rosehead (a shallow pyramid shape). This shape of nail had the benefit of four sharp edges on the shank which cut deep into timber and the tapered shank provided friction down its full length. The wood fibres would often swell if damp and bind round the nail making an extremely strong fixing. In Tudor times we have evidence that the nail shape had not changed at all as can be seen by the nails found preserved in a barrel of tar on board the 'Mary Rose' - the Tudor flag ship of Henry VIII built in 1509 and recovered from the mud of the Solent in 1982.

At the Roman fort of Inchtuthil in Perthshire, a hoard of over 875,000 iron nails weighing 7 tonnes was found. General Julius Agricola governor of Britain set out to defeat the Caledonians in the name of the Roman Empire during the first century AD. During this campaign, the 20th Legion of the Roman Army built the Legionary Fortress of Inchtuthil. This formidable fortress, one of the northern most forts of the Empire, would last as Agricola's base of operations from around 83 - 87 AD. When the Romans abandoned the fort many of the nails from that site were unused, and in part at least the hoard must represent the contents of the legion's "stores". As they were too bulky to move south with the legion, they were hidden in a deep pit to ensure that the Caledonians would not find them. They were scared the Caledonians would melt the iron nails down and hammer them into weapons. The ploy worked as, although the fortress had been known about since the 18th century, the nails were noactually found until 1961.

Machine made nails It was not until around 1600 that the first machine for making nails appeared and tended really to automate much of the blacksmith's job. The 'Oliver' - a kind of work-bench, equipped with a pair of treadle operated hammers - provided a mechanism for beating the metal into various shapes but the nails were still made one at a time.

The wrought iron nails were used until about 1850 for "clenching" to stand the jar in facings of window shutters, battens of doors and the overlay of boards (old style) in lathedroom partitions. They are not however typical of nails used in general house construction, after 1800.

After 1825, with the

use of machines that both cut and headed nails, the shank was similar,

but the head was stamped level, the top being impressed by a single

blow. |

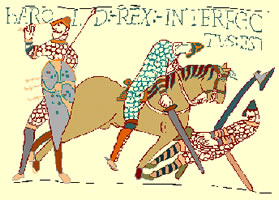

Iron

nails of all sizes were made by the Roman legion's blacksmiths in their

workshop (fabrica) by smelting the iron ore and forming the nails by

hand, producing a square tapered nail with a large head. The larger

nails were used to hold the wooden stockade around the fort in place.

They were also used to bind the timber roofing of the fort buildings.

Iron

nails of all sizes were made by the Roman legion's blacksmiths in their

workshop (fabrica) by smelting the iron ore and forming the nails by

hand, producing a square tapered nail with a large head. The larger

nails were used to hold the wooden stockade around the fort in place.

They were also used to bind the timber roofing of the fort buildings.

Numerous

patents for nail cutting and heading were issued from 1786 on. The combination

machines that cut and headed in one operation were not efficient and

in general use until about 1817-1820. Jeremiah Wilkinson of Cumberland,

RI., is credited with cutting tacks and later nails from sheet metal

from about 1775.

Numerous

patents for nail cutting and heading were issued from 1786 on. The combination

machines that cut and headed in one operation were not efficient and

in general use until about 1817-1820. Jeremiah Wilkinson of Cumberland,

RI., is credited with cutting tacks and later nails from sheet metal

from about 1775.